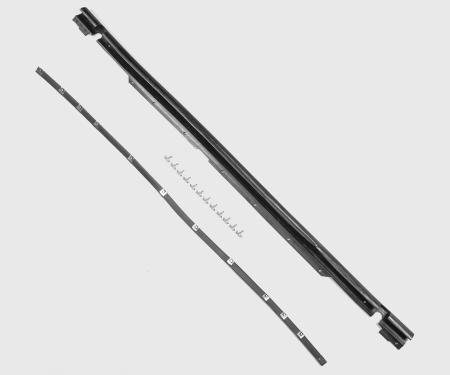

Precision Windshield Frame to Cowl Seal CS 6110 52

- Fitment: Designed for 1952 vehicles using the CS 6110 windshield frame pattern — verify fitment for your specific make/model before purchase.

- Durable rubber construction resists ozone, UV, and temperature extremes for long service life.

- Creates a tight seal between windshield frame and cowl to prevent leaks and reduce wind noise.

- Flexible profile simplifies installation and helps restore factory appearance and fitment.

- Ideal for restoration or replacement applications where original-style sealing and fit are required.

- Difficulty: 2/5

- Estimated time: 30–60 minutes

- flat-head screwdriver or trim tool

- rubber mallet or soft-faced hammer

- weatherstrip adhesive (if specified)

- isopropyl alcohol or degreaser

- clean rags

- gloves

- Remove windshield trim and/or windshield (if required) according to vehicle service manual to access the old seal.

- Carefully pry out and remove the old seal using a trim tool or flat screwdriver; avoid scratching paint or metal.

- Thoroughly clean the cowl and windshield frame mating surfaces with isopropyl alcohol or degreaser and dry completely.

- Test-fit the new CS 6110 52 seal into the cowl channel and against the windshield frame to confirm orientation and fit.

- If manufacturer or vehicle instructions call for adhesive, apply a thin, even bead of recommended weatherstrip adhesive into the cowl channel or to the seal bead.

- Seat the seal into the cowl channel, working around the perimeter and using a rubber mallet or hand pressure to fully engage the seal lip into the channel.

- Reinstall windshield and/or trim per vehicle service procedures, ensuring the seal is properly compressed and seated to form a continuous gasket.

- Allow any adhesive to cure per the adhesive manufacturer’s instructions, then inspect for gaps, leaks, or misalignment and make necessary adjustments.

Since 1986 Precision Replacement Parts has been a trusted name in the Automotive Glass Industry.

Our knowledge and experience in manufacturing millions of extruded and molded EPDM Rubber, PVC and HDPE based plastics, and various stamped and extruded metal products for the classic and late model industries has allowed Precision to expand our services into multiple product markets.

Along with our own USA based production facility, Precision also partners with 25 different manufactures worldwide with a reputation as a global leader supplying OEM and replacement products to a number of different industries. Our partnerships along with our own in-house manufacturing and fabrication capability gives Precision a unique position in helping to meet the expanding needs of customers everywhere, providing them with a sustained competitive advantage.

Vehicle Fitment:

| Make | Model | Submodel | Years |

| Jeep | CJ5A | 1966 - 1968 | |

| Jeep | CJ5 | 1959 - 1975 | |

| Jeep | CJ6A | 1966 - 1968 | |

| Jeep | CJ6 | 1959 - 1975 | |

| Jeep | DJ5 | 1965 - 1975 | |

| Jeep | DJ6 | 1965 - 1968 | |

| Jeep | Willys | CJ-5 | 1955 - 1958 |

| Jeep | Willys | CJ-6 | 1956 - 1958 |

Specifications:

| Part Type | Cowl Seal |

| Proposition 65 | www.P65Warnings.ca.gov |

| Warranty | Lifetime on Defects TX |