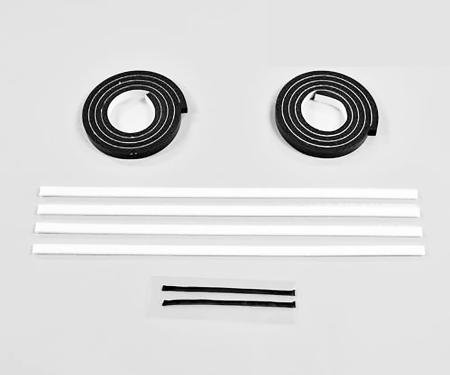

Precision Hardtop, Sedan, Wagon Models - Windshield Weatherstrip Seal Without Trim Groove WBL D646

- Designed for hardtop, sedan, and wagon body-style applications without a trim groove.

- Premium EPDM rubber construction resists UV, ozone, and temperature degradation.

- Seals windshield to body to prevent water leaks, drafts, and wind noise.

- No trim groove profile for a clean, flush installation where trim is not used.

- OEM-style fit and finish ideal for restorations and replacement projects.

- Easy to seat and trim for a precise fit; long-lasting durability for maintenance use.

- Difficulty: 2/5

- Estimated time: 30-60 minutes

- Plastic trim removal tool or flat screwdriver (wrapped to avoid marring)

- Razor knife or sharp trimming blade

- Weatherstrip adhesive (if required)

- Cleaning solvent or isopropyl alcohol

- Lint-free cloth

- Gloves

- Park vehicle on level ground and protect painted surfaces with masking tape or cloth around the windshield area.

- Carefully remove the old weatherstrip: pry out the seal using a plastic trim tool or wrapped flat screwdriver, working slowly to avoid bending the windshield or damaging paint.

- Clean the channel and surrounding flange thoroughly with solvent or isopropyl alcohol to remove adhesive, dirt, and old seal residue. Allow to dry completely.

- Test-fit the new weatherstrip along the windshield opening to confirm orientation and length. If the seal is longer than required, mark trimming locations.

- If the fitment or vehicle service manual calls for adhesive, apply a thin, even bead of weatherstrip adhesive to the channel or seal lip per adhesive instructions; many applications will seat without glue but adhesive improves long-term hold.

- Starting at the top center of the windshield, press the seal into the channel and work outward toward both hood sides, ensuring the seal lip seats evenly and fully into the flange. Use firm hand pressure or a soft roller to seat the rubber.

- Trim any excess material at the corners or ends with a razor knife for a neat finish. Re-check the seal around the entire perimeter for full engagement.

- Allow adhesive to cure as specified by the adhesive manufacturer before exposing the vehicle to moisture or driving at high speeds. Recheck after first rain to ensure there are no leaks.

Since 1986 Precision Replacement Parts has been a trusted name in the Automotive Glass Industry.

Our knowledge and experience in manufacturing millions of extruded and molded EPDM Rubber, PVC and HDPE based plastics, and various stamped and extruded metal products for the classic and late model industries has allowed Precision to expand our services into multiple product markets.

Along with our own USA based production facility, Precision also partners with 25 different manufactures worldwide with a reputation as a global leader supplying OEM and replacement products to a number of different industries. Our partnerships along with our own in-house manufacturing and fabrication capability gives Precision a unique position in helping to meet the expanding needs of customers everywhere, providing them with a sustained competitive advantage.

Vehicle Fitment:

| Make | Model | Years | Fitment Notes |

| American Motors | American | 1966 - 1968 | Wagon Sedan Hardtop |

| American Motors | Rambler | 1969 | Wagon Sedan Hardtop |

Specifications:

| Part Type | Windshield Seal |

| Proposition 65 | www.P65Warnings.ca.gov |

| Warranty | Lifetime on Defects TX |