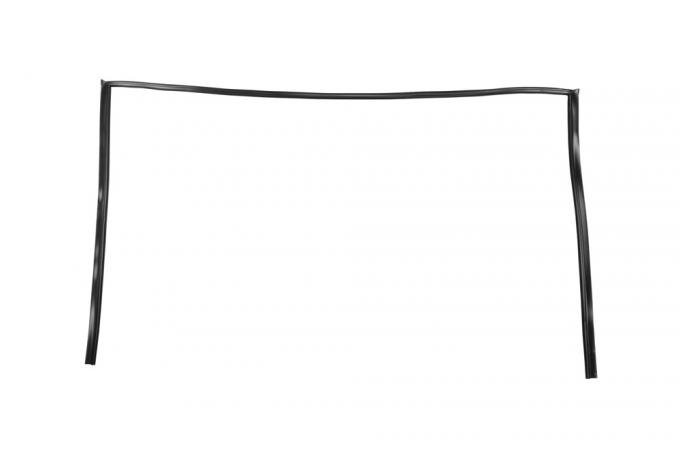

Precision Windshield Molding WFS D998

- Weather-resistant EPDM construction for long-lasting durability and UV resistance.

- Profile matches OEM contours for a snug, factory-style fit and finish.

- Secures and seals the windshield edge to reduce leaks and wind noise.

- Protects windshield bead from chips, abrasion, and corrosion.

- Straightforward replacement for worn, cracked, or missing moldings—restoration-ready.

- Corrosion-resistant internal retention channel holds molding securely in place.

- Difficulty: 3/5

- Estimated time: 45–90 minutes

- plastic trim removal tool

- flat screwdriver

- rubber mallet or soft-faced hammer

- clean lint-free cloths

- adhesive remover or isopropyl alcohol

- automotive primer/sealer (if specified by vehicle)

- windshield molding adhesive or double-sided automotive tape

- safety gloves

- eye protection

- Confirm part number and dry-fit the molding to the windshield area to verify correct orientation and fit.

- Carefully remove the old molding: use a plastic trim tool to pry the edge away, working slowly to avoid scratching glass or paint. If fasteners are present, remove them first.

- Clean the windshield flange and surrounding pinch-weld area thoroughly with adhesive remover or isopropyl alcohol. Remove all old adhesive, dirt, and corrosion. Allow surface to dry.

- Inspect the pinch-weld and glass bead; repair any rust, dents, or damaged sealant before installing the new molding.

- If recommended for your vehicle, apply a thin coat of automotive primer/sealer to the pinch-weld and allow to flash per product instructions.

- Apply the appropriate molding adhesive or double-sided automotive tape to the pinch-weld or to the inner channel of the new molding, following adhesive manufacturer instructions.

- Starting at one corner, press the molding into place along the windshield edge. Use even pressure and a rubber mallet or soft-faced hammer wrapped in a cloth to seat the molding without damaging the finish.

- Trim any excess molding material with a utility knife if required, and reinstall any retained clips or trim pieces removed earlier.

- Allow adhesive to cure fully per the adhesive manufacturer’s recommendations before driving; recheck fitment and seal after cure.

- If you encounter fitment issues or extensive corrosion, consider professional installation—some vehicles require partial or full windshield removal for proper replacement.

Since 1986 Precision Replacement Parts has been a trusted name in the Automotive Glass Industry.

Our knowledge and experience in manufacturing millions of extruded and molded EPDM Rubber, PVC and HDPE based plastics, and various stamped and extruded metal products for the classic and late model industries has allowed Precision to expand our services into multiple product markets.

Along with our own USA based production facility, Precision also partners with 25 different manufactures worldwide with a reputation as a global leader supplying OEM and replacement products to a number of different industries. Our partnerships along with our own in-house manufacturing and fabrication capability gives Precision a unique position in helping to meet the expanding needs of customers everywhere, providing them with a sustained competitive advantage.

Vehicle Fitment:

| Make | Model | Years |

| Dodge | Shadow | 1987 - 1994 |

| Plymouth | Sundance | 1987 - 1994 |

Specifications:

| Part Type | Windshield Molding |

| Proposition 65 | www.P65Warnings.ca.gov |

| Warranty | Lifetime on Defects TX |