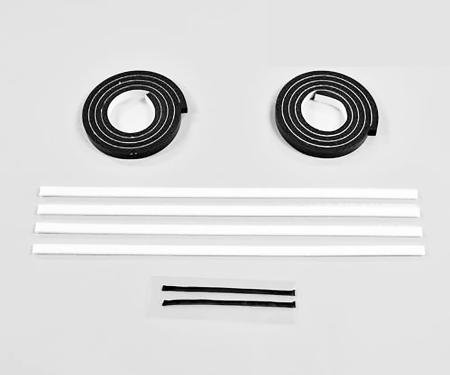

Precision Large - Rear Window Weatherstrip Seal, With Trim Groove for lockstrip WCR D1048 T

- Designed for rear window applications using the WCR D1048 T lockstrip profile.

- Durable EPDM rubber resists UV, ozone, and temperature extremes for long service life.

- Integrated trim groove accepts a lockstrip to secure and align the glass.

- Creates a watertight seal to prevent leaks and reduce wind noise and vibration.

- Flexible and resilient for easier installation and a factory-like fit.

- Ideal for restorations and replacement of worn or cracked rear window seals.

- Difficulty: 2/5

- Estimated time: 45–90 minutes

- flat trim tool or plastic pry tool

- rubber mallet or block of wood

- soapy water or window lubricant

- clean rags and isopropyl alcohol

- utility knife or heavy-duty scissors

- heat gun or hair dryer (optional)

- screwdrivers or trim fastener tools (if required)

- Remove the interior trim and old weatherstrip, then carefully lift out the rear glass per vehicle service procedures.

- Clean the window channel and glass edge thoroughly with isopropyl alcohol to remove old adhesive, dirt, and sealant.

- Test-fit the new weatherstrip over the glass edge and into the channel to confirm orientation and fit. Trim excess if necessary.

- Apply a light coating of soapy water or approved window lubricant to the channel and seal to ease installation.

- If using a lockstrip, seat the lockstrip into the weatherstrip’s trim groove before installing the assembly into the channel.

- Starting at one corner, press the seal into the channel, working around the perimeter. Use a rubber mallet or block of wood to gently tap the seal fully into place without damaging it.

- Use a heat gun on low setting only if needed to make the rubber more pliable for tight corners; avoid overheating which can deform the seal.

- Trim any excess material with a utility knife for a clean finish and reinstall interior trim pieces and hardware to factory specifications.

- Perform a water test (hose) and check for wind noise; adjust or reseat the seal if minor leaks or gaps are found.

Since 1986 Precision Replacement Parts has been a trusted name in the Automotive Glass Industry.

Our knowledge and experience in manufacturing millions of extruded and molded EPDM Rubber, PVC and HDPE based plastics, and various stamped and extruded metal products for the classic and late model industries has allowed Precision to expand our services into multiple product markets.

Along with our own USA based production facility, Precision also partners with 25 different manufactures worldwide with a reputation as a global leader supplying OEM and replacement products to a number of different industries. Our partnerships along with our own in-house manufacturing and fabrication capability gives Precision a unique position in helping to meet the expanding needs of customers everywhere, providing them with a sustained competitive advantage.

Vehicle Fitment:

| Make | Model | Years |

| Dodge | D100 Pickup | 1968 - 1971 |

| Dodge | D100 Series | 1961 - 1967 |

| Dodge | D200 Pickup | 1968 - 1971 |

| Dodge | D200 Series | 1961 - 1967 |

| Dodge | D300 Pickup | 1968 - 1971 |

| Dodge | D300 Series | 1961 - 1967 |

| Dodge | W100 Pickup | 1968 - 1971 |

| Dodge | W100 Series | 1961 - 1967 |

| Dodge | W200 Pickup | 1968 - 1971 |

| Dodge | W200 Series | 1961 - 1967 |

| Dodge | W300 Pickup | 1968 - 1971 |

| Dodge | W300 Series | 1961 - 1967 |

Specifications:

| Part Type | Back Glass Seal |

| Proposition 65 | www.P65Warnings.ca.gov |

| Warranty | Lifetime on Defects TX |